• Carbide Liners:

Shield chutes,

hoppers, and transport equipment from continuous abrasion, minimizing downtime

and component replacement

• Carbide Plates and Tiles:

Protects crushers,

mills, and conveyors in high-wear zones

• Carbide Grinding Wheels:

Delivers precise

finishing on hard materials with accuracy and wear control.

• Carbide Mixing Blades:

Carbide excels in impact wear for mining, construction,

crushing, and drilling, combining hardness and toughness to outperform

traditional alloys

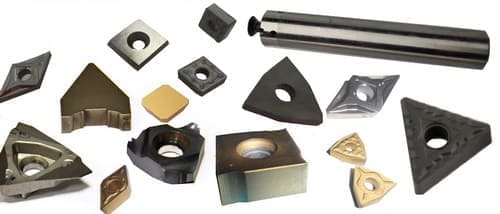

• Carbide Inserts:

Edge stability and precision under heavy impact in machining and drilling

• Carbide Hammers:

Fractures hard materials in mills and crushers with lasting performance.

• Carbide Tips for Mining and Drilling:

Extend tool life and reliability under repeated shock and abrasion.

Tungsten carbide resists corrosive fluids with superior leak prevention, low friction, and high wear resistance—ideal for petrochemical, offshore, and fluid-handling systems.

• Carbide

Seals:

Ensures containment in pumps and valves under corrosion.

Cemented carbide provides high hardness, low friction, and excellent anti-adhesion properties—ideal for guide rails, piston rings, and other critical components in high-frequency, high-pressure applications.

• Carbide Guide Plates:

Protects

linear-motion parts for alignment and wear control

• Carbide Rails and Guides:

For conveyors:

lasting operation under abrasive loads.

• Carbide Piston Rings:

Cemented carbide is the “wear-resistant heart” of rotating machinery, combining hardness, toughness, and thermal stability for aerospace, energy, and heavy industries.

• Carbide Rotary Cutters:

Precision tools

for machining hard materials with superior edge retention

• Carbide Saw Tips:

For saw blades in

wood and metal cutting, ensuring lasting sharpness.

• Carbide Bearings:

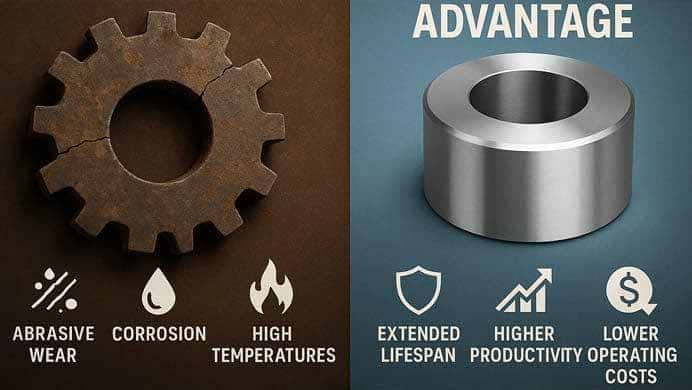

Cemented carbide excels

where other materials fail, withstanding heat, oxidation, and deformation. Its

thermal stability and strength make it essential for extreme temperatures and

harsh wear.

• Carbide Heat Shields:

Protects equipment from thermal stress in high-heat environments.

Advanced tungsten carbide

parts surpass conventional wear components, extending equipment life and

boosting performance with tailored solutions for aging machinery.

• Carbide Buttons:

Built to withstand

extreme abrasion in mining and drilling

• Carbide Sleeves and Rings:

Deliver long-term

protection for shafts and bearing systems

• Carbide Custom Molded Parts:

• Carbide Knives and Blades:

Ideal for cutting

hard materials with durable edges and precise accuracy

• Carbide Rollers:

Used in mills and

conveyors for lasting performance and surface protection

• Carbide Scrapers:

With more than three decades of specialized experience, we deliver high-precision tungsten carbide components engineered to perform reliably in the most demanding industrial environments.

Backed by internationally recognized quality management and environmental standards, we ensure consistent product quality and sustainable manufacturing practices.

Tailored engineering solutions designed to meet your specific operational challenges and performance requirements, delivering optimal results across diverse manufacturing sectors.