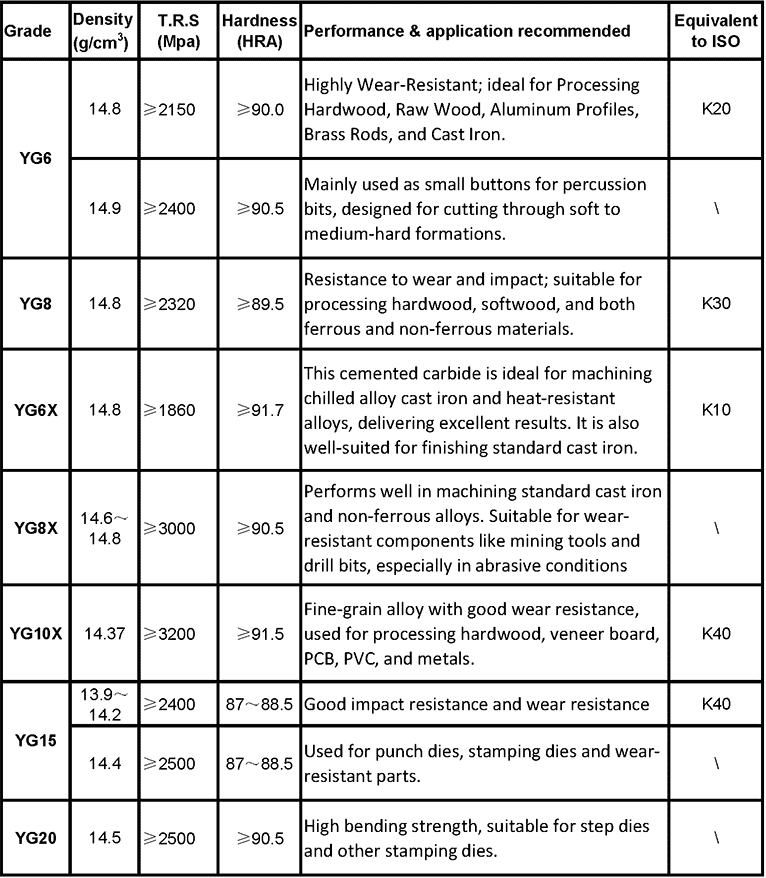

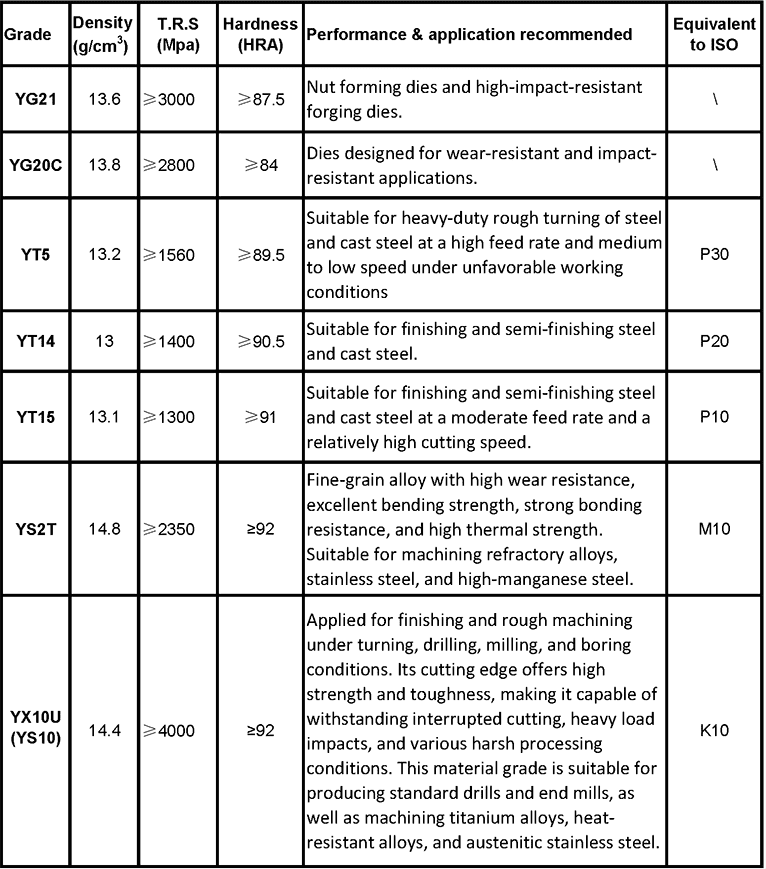

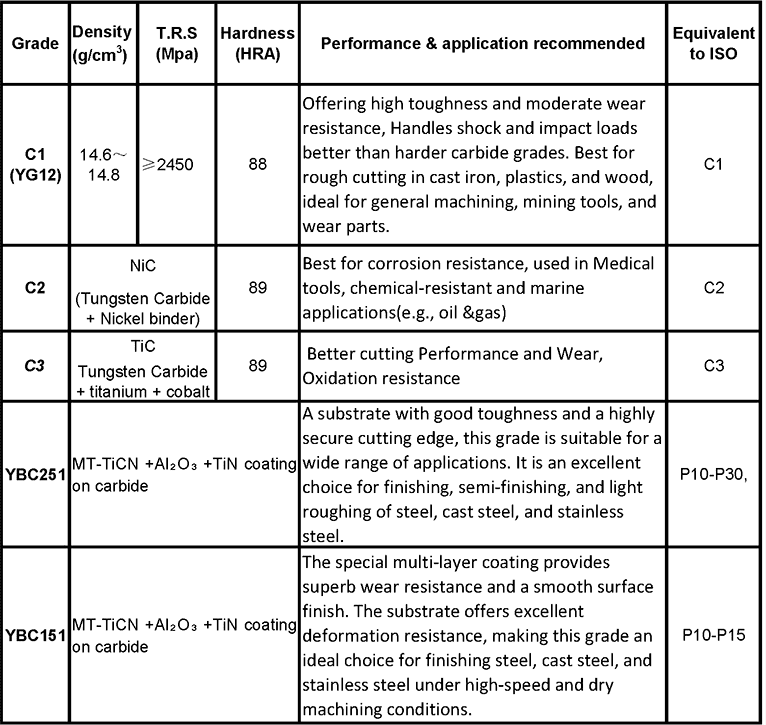

| Tungsten Carbide Grades & Quality | |||||

| Remarks: | |||||

| 1. K10-K20: Carbide K-grade materials offer high wear resistance, excellent thermal stability, brittle-resistant performance, and long tool life, making them ideal for high-speed cutting and abrasive conditions. (YG Series: Tungsten Carbide + Cobalt binder ) | |||||

| 2. P10-P20: Carbide P-grade materials are primarily designed for machining steel and tough alloys. They offer a balance of high toughness, wear resistance, and thermal stability, making them ideal for applications involving high-speed cutting and interrupted cuts.(YT Series: Tungsten Carbide+Titanium+Cobalt) | |||||

| 3. M10-M20: Carbide M-grade materials are specifically designed for machining stainless steel, cast iron, and non-ferrous metals. They offer a balance of wear resistance and toughness, making them ideal for applications that involve interrupted cuts, high heat, and work hardening materials. | |||||

| 4. S10-S20: Carbide S-grade materials are specifically designed for machining superalloys, heat-resistant alloys (HRAs), and titanium-based materials. They offer exceptional wear resistance, high-temperature stability, and toughness, making them ideal for extreme cutting conditions where tools are exposed to high stress and heat. | |||||

| 5. C10-C20: Carbide C-grade materials are specifically designed for machining cast iron and non-ferrous metals. They offer excellent wear resistance, hardness, and thermal stability, making them ideal for applications requiring high durability. | |||||

| 6. We have the capability to manufacture custom carbide tools and accessories in unlisted grades according to customer requirements. |