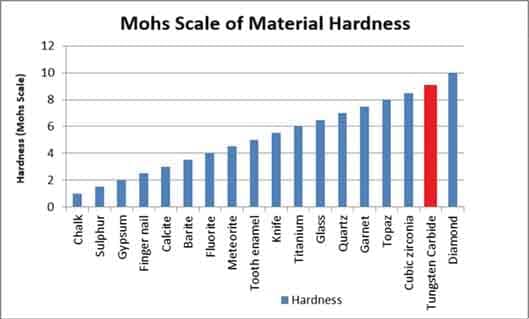

Oil and gas operations demand materials that deliver safety, efficiency, and durability. Tungsten carbide is the proven choice for extreme drilling, cutting, and flow-control applications.

At Tungsten C Tools, we engineer custom tungsten carbide components—valve seats, seals, drill bit inserts, and flow restrictors—built to withstand high pressure, temperature, and abrasion. Backed by decades of expertise and strict quality control, our solutions provide unmatched reliability and help reduce downtime

We don’t offer off-the-shelf solutions—we design and manufacture tungsten carbide components tailored to withstand the unique wear, pressure, and corrosion challenges of oil and gas operations.

Our proprietary carbide blends are optimized for strength, hardness, and longevity in extreme service environments—including formulations enhanced with titanium carbide and tantalum carbide additives.

We provide responsive technical service backed by ISO-compliant manufacturing, short lead times, and consistent product quality—earning the long-term trust of drilling and equipment companies.

Masterfully engineered Tungsten Carbide parts to serve your oil site from initial exploration drilling to blades for pipe cutting, and high pressure valve seats.

We take pride in the rigorous quality control measures integrated throughout our manufacturing process to deliver superior quality to our customers

With more than three decades of specialized experience, we deliver high-precision tungsten carbide components engineered to perform reliably in the most demanding industrial environments.

Backed by internationally recognized quality management and environmental standards, we ensure consistent product quality and sustainable manufacturing practices.

Engineered to overcome tough challenges and deliver reliable, high-performance results — ensuring durability and efficiency from exploration to production.